Tests on

Bottles: Glass or PET and Preforms

Caps: Aluminium, other metal, plastic

Cans: Aluminium, others

Pots: caps, film, blisters etc.

Leak detection by setting vacuum

with or withouht step

VLT-ST is equipped with a touching screen. It‘s visual and easy to operate. Adjustable vacuum and holding time stage setting, meets different test requests of various products.

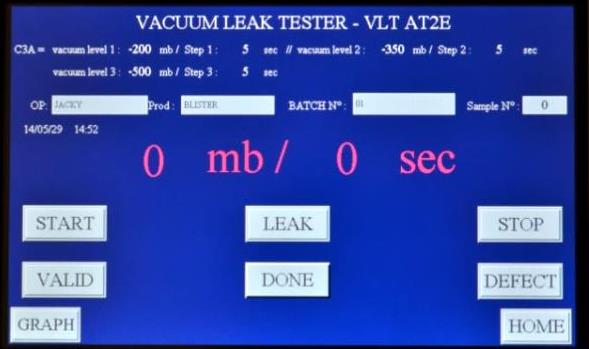

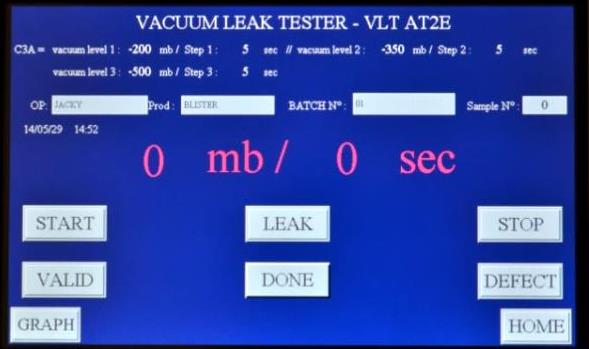

Testing screen

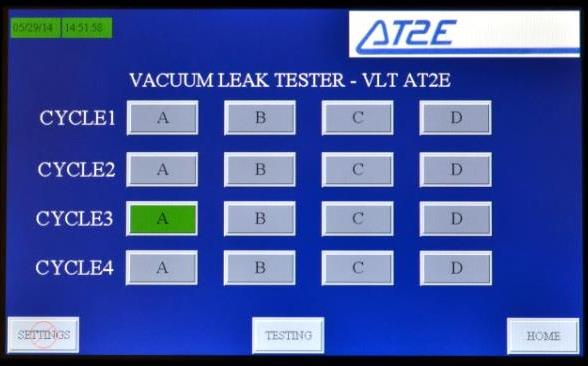

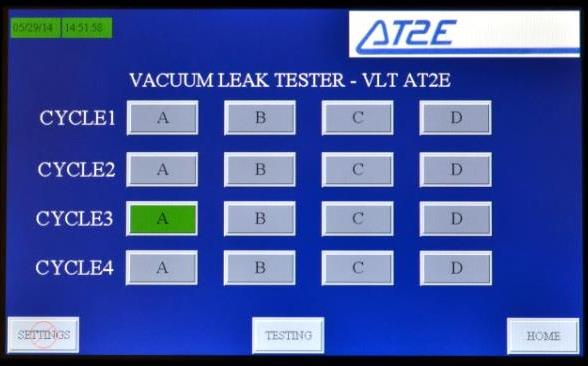

Cycle selecting screen

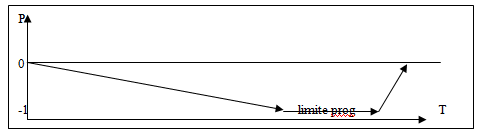

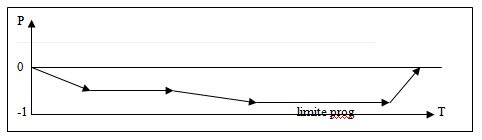

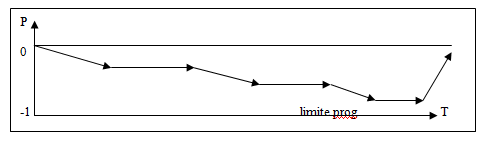

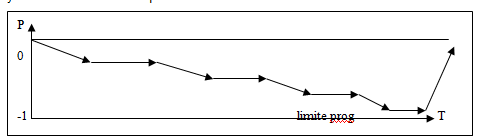

Test curve

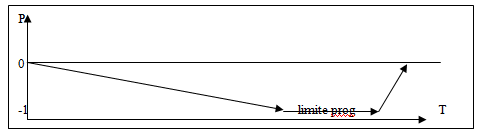

Cycle 1

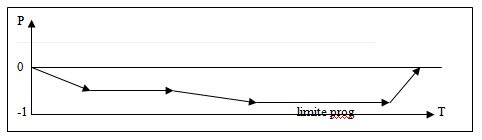

Cycle 2

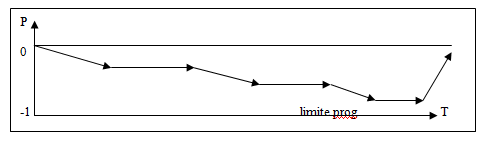

Cycle 3

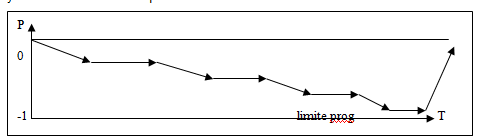

Cycle 4

Technical specifications

- Vacuum adjustable up to - 999 mb

- Box with dimensions upon request

- Box made of polished transparent PMMA (very rugged)

- Easy to use and safe by touch screen PLC Control Panel

- Dynamic display: Testing status / Date and time

- Display: Product name / Operator / Lot No. / Sample No.

- User defined test cycle (up to 16 modes). Pre-define up to 4 steps of each test. Vacuum level and holding time adjustable

- For each step. Satisfies different kinds of testing request

- Easy operation, only to select the pre-defined mode forstarting a test no need to set the parameters every time

- 10 operators and 30 products memorisable

- Lot No. and Sample No. editable

- Review of the testing curve

- RS 232 C output

- Accuracy: 0.5% of the measure

- Delivered with high performance vacuum pump

- Runs with 6 bar network

- Runs with 6 bar network

01

Optional parts

- Immersion system

- Shelf structure

- High performance pump (vacuum -999 mb)

Mini printer (Optional)

02

Box with front door and shelves

Box with immersion system