Measuring principle

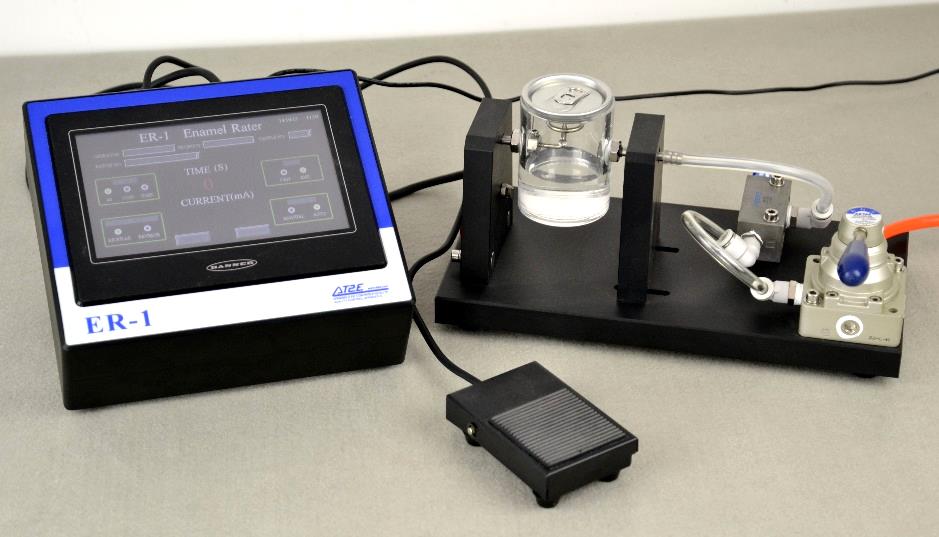

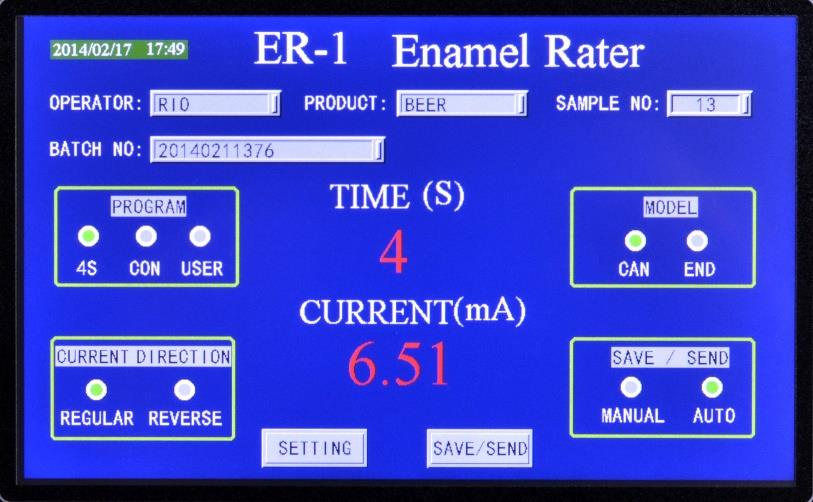

The instrument applies a constant micro-voltage across the can body and an electrode immersed in the electrolyticwater filled, and measuring the resulting current. Voltage during the test is 6.3 V DC. The operating range is 0 to 300 milliampere with an accuracy of resolution of 0.01 milliampere.

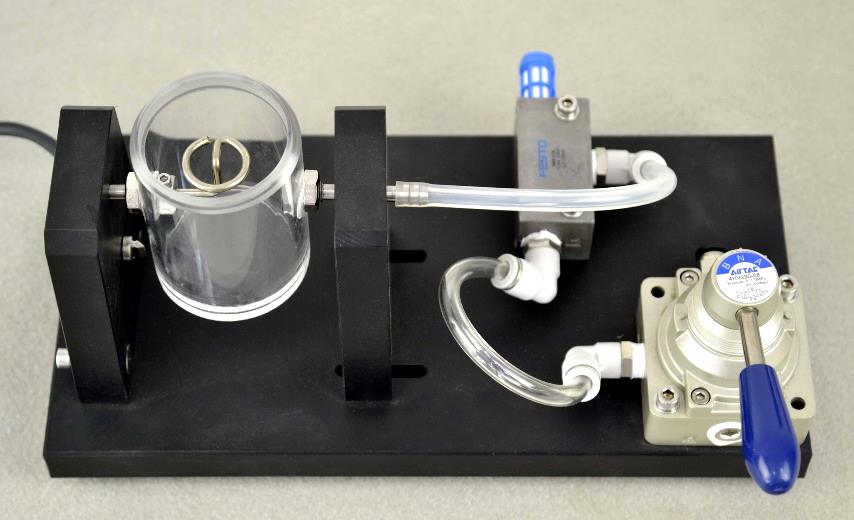

The cover support comprises a container mounted on a pivot. The cup is beveled to make a tight seal on the can cover. An electrode and the connection to the vacuum in the container are mounted. On the base, a valve for creating a vacuumand a movable arm, complete the electrical circuit when the assembly is inverted.