Professional program, flexible, quick

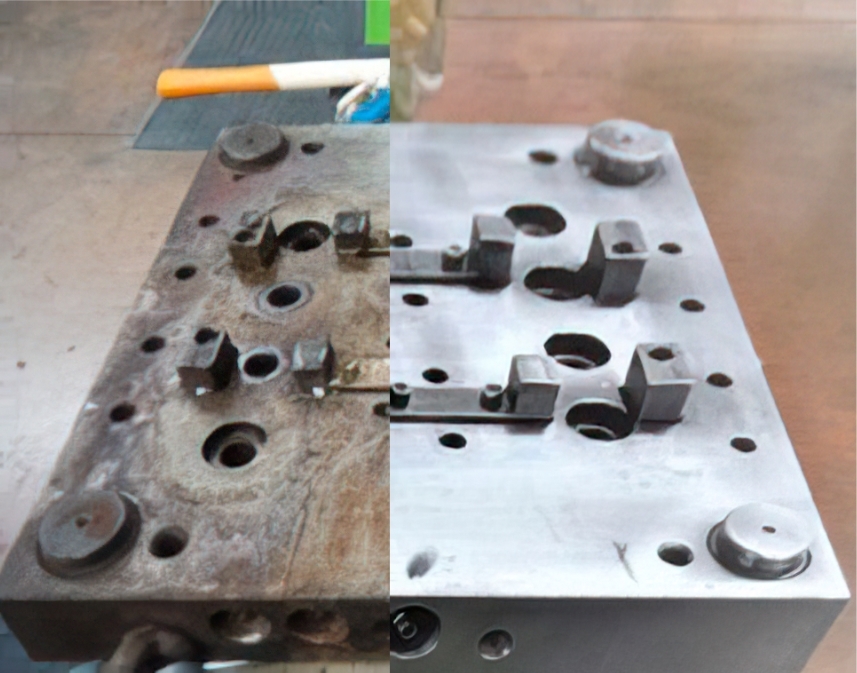

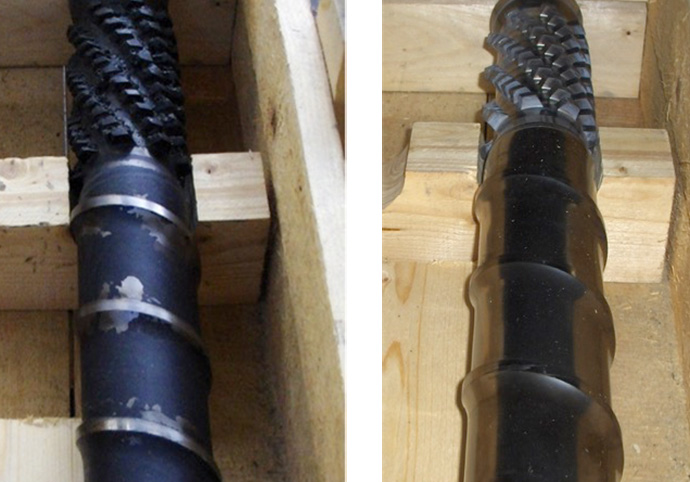

Our unique thermal chemical cleaning process removes all plastic, carbon, degraded material, and inorganic contamination from metal tools and machine parts. We work all resins, including elastomers, engineered plastics, and glass filled grades.