Mode details

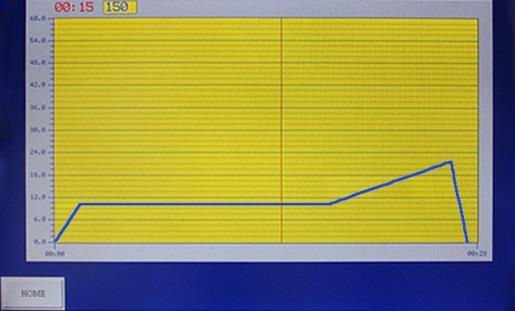

Fill ramp mode

The filling ramp mode is designed to simulate the situation of filling lines of PET bottles. Under this mode, the PET bottles are pressurized rapidly to the initially preset pressure and maintained for a given time (for example 13 seconds). Then continue to increase the pressure with a speed of 0.7 bar/s (speed is settable) until the outbreak of the bottle or reaching the max pressure or volume. Preset parameter includes: initial screening pressure, Hold time and ramp speed.

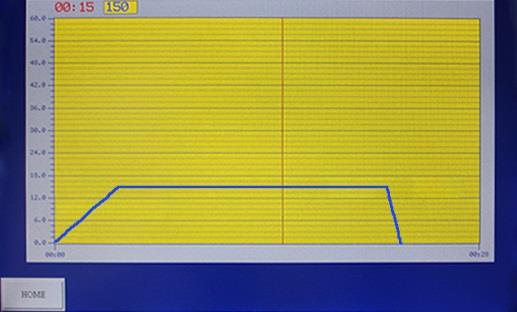

Burst mode

Under this mode, PET bottle will be pressurized rapidly to the initially preset pressure and maintained for a predefined period. Preset parameter includes: initial pressure, Hold time and Expansion limit.

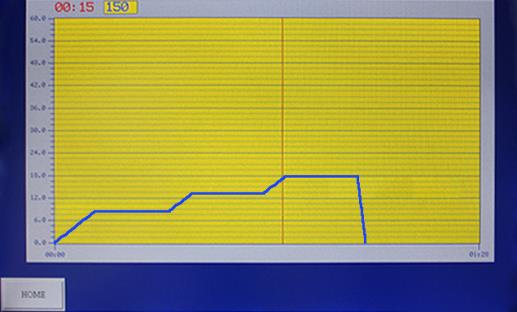

Custom mode

Under this mode, user is able to create the pressure curve to meet the particular conditions of control. Users can definethe pressure curve by steps, after the adjustment is made, the corresponding curve will be displayed on the user interface.