dimensional and wall thickness measurements

PRODUCTS

Accurate Magnetic Thickness Gauge

Height Gauge

Circometer and Caliper

Base Clearance Gauge

Glass Bottle Lightening System

Preform Cutter

Preform & Bottle Measuring System

Perpendiculary Gauges

Thickness Gauges

Fill Hight Gauges, Fill Hight Syringe

Automated Preform & Bottle Dimension Tester

Gauge Data Transportation Box

AMTG-2 Accurate Magnetic Thickness Gauge

Description

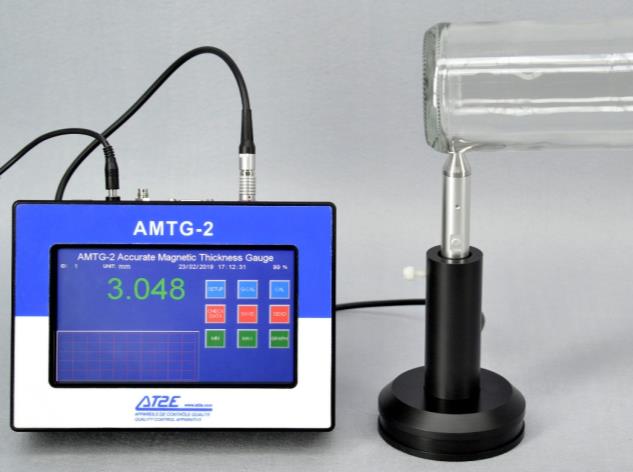

The "AMTG-2" is a portable feeler gauge. It is used to

measure the thickness of non-magnetic materials, such as plastic, glass, ceramic, aluminum, titanium, copper

etc... The accuracy of the measurement is not affected by the shape of the samples.

It’s designed by

basing on the method of the Hall Effect. Simple and rapid measure as below:

- Place the steel ball on

one side of the sample and the probe on the opposite side

- Move the sample and let the probe to be the

tested position

- The steel ball will be drawn by the probe automatically

- The Hall Effect sensor on

the probe measures the distance between the probe tip and the steel ball

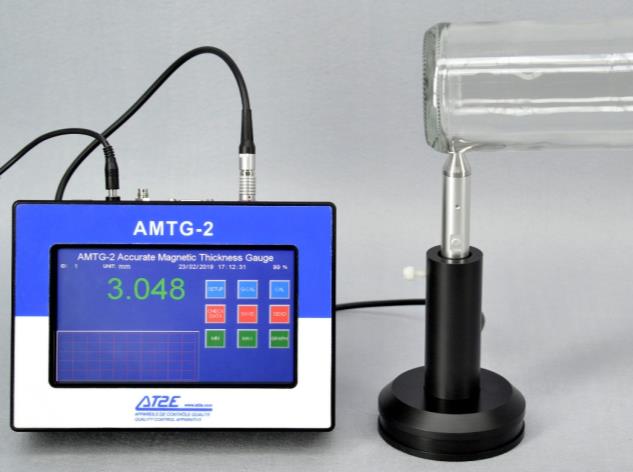

AMTG-2 with probe

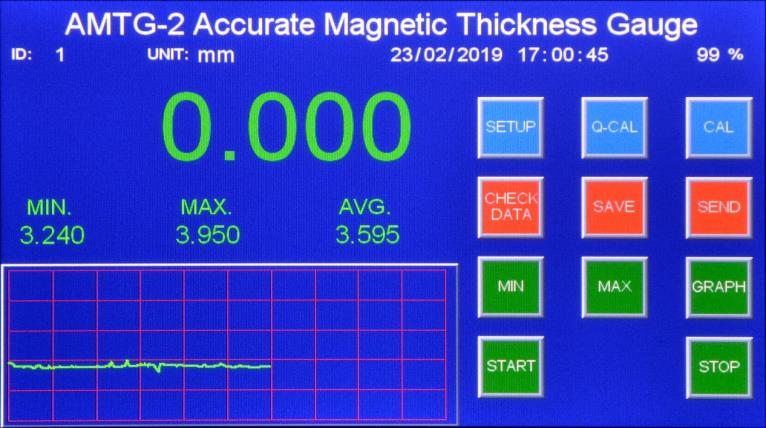

Main interface

Advantages

- Non-destructive measure

- High resolution 7” touching screen

- Dynamic display: measuring value / graph /

date / hour / battery life

- Full aluminum frame

- Fast and accurate measurement of the thickness

- Achieving accurate thickness measurement in corners, small

radius and some irregular shape

- Alarm function: Programmable, warns the

high or low preset value by sound or visual indication

- Password function enables the safety of the calibration

data and measuring data

- Display real-time measurement value

- Max. and Min. mode: Automatic capture of

the maximum or minimum value

- Value difference function: Display the

value difference between preset value and actual measured value

- YCLE” function: Record the Max, Min,

Average value & Graph during a predefined time. “Delayed start & Auto�stop”

function frees the hands of operator and it’s convenient for large-size sample measuring

- Can store 9999 measurement data

01

Technical characteristics

- Measure mode: Normal / High accuracy

- Display mode: Real-time / Minimum or

Maximum

- Resolution: 0.01 mm or 0.001 mm (0.001

inch or 0.0001 inch)

- Display: TFT screen displays the real time

reading, minimum reading, alarm status and data info

- Outputs: RS-232

- Calibration: Multi-point calibration (up

to 21 points)

- Power supply: AC 110 - 240 V 50/60 Hz

- Battery: Rechargeable lithium battery.

Full loaded working time without charging is approx. 2-3 hours

- Units: mm / Inch

- Language: English

- Dimensions: 210 x 150 x 65 mm

- Net weight: 2 kg (Package weight: 5 kg)

- Measure range and accuracy (Custom made for range 0-4 mm or

0-8 mm)

02

Plastic Measuring

Preform Measuring

Glass Measuring

Aluminum Measuring

Portable case

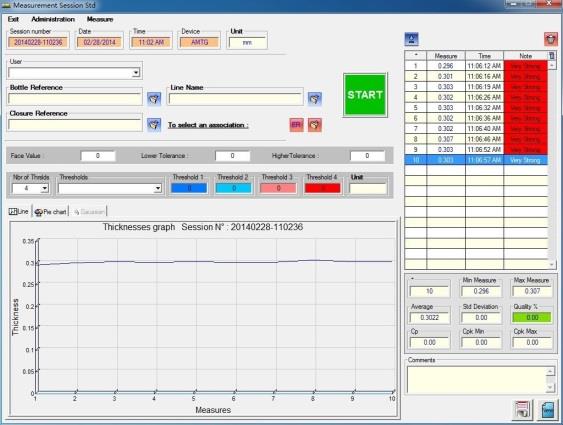

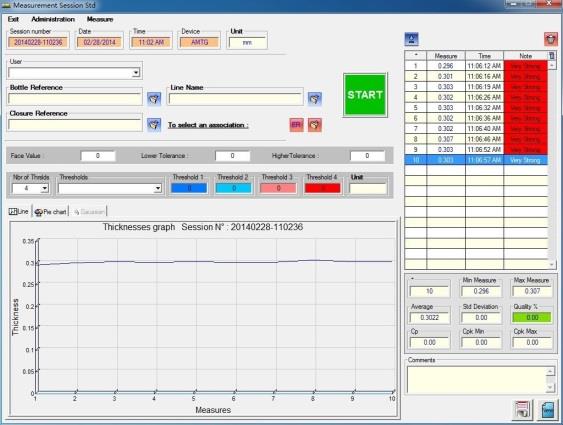

“QualiMesure” Software (Optional)

Standard configuration

- Standard probe with cable and stand

- Using manual

- Charger

- Steel balls and supports

Included : 1.59 / 3.18 / 4.76

mm (3.18 / 4.76 / 5.00 mm for 0-8 mm model)

- Foot switch

- Portable case

- Calibration blocks (Calibration blocks configuration to be

subject to the measure range)

03