dimensional and wall thickness measurements

PRODUCTS

Accurate Magnetic Thickness Gauge

Height Gauge

Circometer and Caliper

Base Clearance Gauge

Glass Bottle Lightening System

Preform Cutter

Preform & Bottle Measuring System

Perpendiculary Gauges

Thickness Gauges

Fill Hight Gauges, Fill Hight Syringe

Automated Preform & Bottle Dimension Tester

Gauge Data Transportation Box

Automated Preform/Bottle Dimension Tester

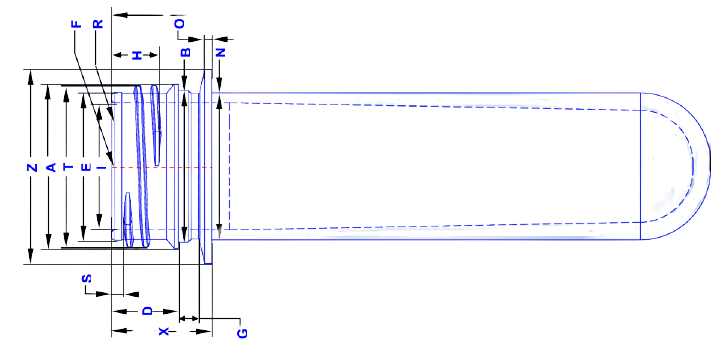

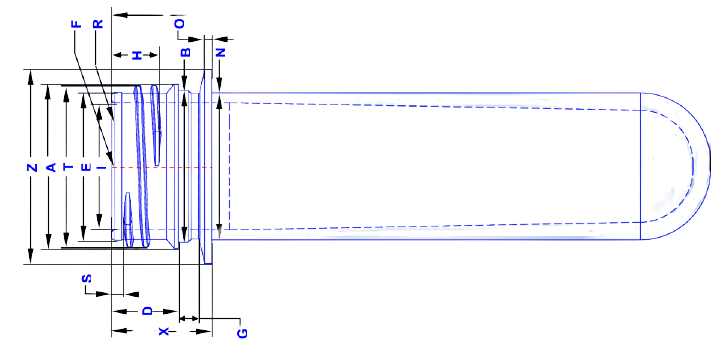

Description

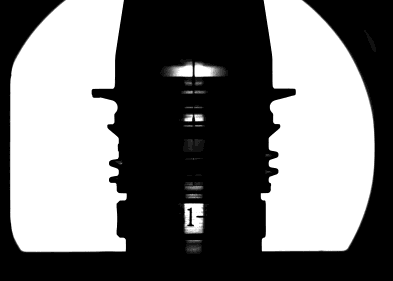

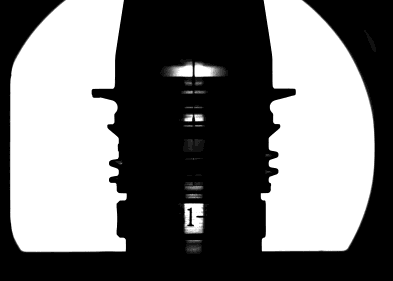

The Automated Preform/Bottle Dimension Tester is an automatic

instrument for testing the general dimension of preforms. The instrument is designed according to the

principle of optical multi-lens refraction and segmented imaging, and multi-segment parallel light is used

to illuminate the preform to obtain the entire contour image.

The contour was extracted by the

bi-telecentric lens and parallel light source, which ensures that the contour is not deformed, and the

measurement accuracy is ensured.

Auto positioning and measuring the dimensions of the

preform/bottle, not only the regular dimensions like neck diameter, thread diameter and the outer diameter

of locking ring, etc., but also the flashing, concentricity and overall height, wall thickness, etc., the

instrument can also recognize and record the cavity number automatically.

"A" Tamper Band Dia.

"B" PP Band

Diameter

"C" Thread Projection

"D" Distance Tamper Band

"E" Neck

Dia.

"F" Flashing

"G" PP Band Clearance

"H" Distance

Thread End

"I" Neck Inner Dia.

"L" Overall height

"O" OD Band

Thickness

"R" Seal Radius

"S" Distance Thread Start

"T" Thread

Dia.

"U" WT Difference

"V" Thread Tip

Width

"W"Concentricity

"X" Finish Height

"Y" Thread Angle

"Z"

OD Band Dia.

Cavity No. recognition

Wall thickness

Characteristics

- Non-destructive he instrument is designed according to the

principle of optical multi-lens refraction and segmented imaging, and multi-segment

parallel light is used to illuminate the preform to obtain the entire contour image

- Optimal light source design, auto filter the shrinkage and

grain effects caused by the injection molding of the preform, and recognize the

characters of cavity number of the preform accurately

- Custom-made finish spacers according to the finish sizes,

easy to replace and ensure the measurement accuracy

- Preform rotation by servo motor

- Positioning by the inherent characteristic points of the

preforms, so that to standardize the measurements of all the preforms

- Modular design, which is easier in installation, more

convenient to use and higher accuracy and stability

- System adopts measurement modular management function and

improves the measurement accuracy to 1/3~1/5 pixels (0.005mm) through the sub-pixel

image processing technology of planting technology

- Software has different built-in standard finish measurement

modules the system is able to select different measurement modules intelligently by auto

identifying the preform category

- The system has character learning and recognition

functions. Based on the character pre-learning, the cavity number on the preform can be

quickly identified and recorded in the data sheet

01

Auto cavity no. recognition

Parting line measurement

Technical specifications

- Sample dia.: ≤ Φ40mm

- Sample height range: 0 - 30mm, 60 -

180mm(other range by order)

- Measure scope: General dimension of

preform (including wall thickness, inner diameter and thread angle)

- Photographing Chip: 10 Million Pixels,

Black and White Coms

- Lens: Bi-Telecentric Lens

- Display: 12" Touch Screen

- Lighting: Telecentric Parallel Light

- Languages: English / Chinese

- Working Ambient Temperature: 10 – 36°C

- Measuring Accuracy: 0.005mm

- Repeatability accuracy:

±0.01mm

(Neckinner dia. ±0.02mm, Wall Thickness difference ±0.03mm,Flash ±0.025mm, Overall

Height ±0.05mm, Concentricity ±0.05mm, Thread angle ±1°)

- Operation time: 35 - 50 s

- Storage Capacity and Output Format: 64G,

Csv

- Interface Type: USB 2.0/3.0, Gigabit

Network

- Operation System: Windows

- Power Supply: AC 110V / 220V 50Hz/60Hz

- Working Ambient Humidity: 20 - 60% Rh, No

Condensation

- Dimension: 760 (L) x 280 (W) x 435 (H) mm

02