can and end testing equipments

PRODUCTS

Enamel rater for can and tube

Can Leak Analyzer

Seam projector

Seam saw

Dimensional control equipment for cans

Metal End testers

ACBT-1 Aerosol Can Burst Tester

Description

The ACBT-1 is an instrument for testing the internal pressure resistance of aerosol can (for both 3-pcs aerosol can and mono-block aerosol can). It has been widely used by the aerosol can manufacturers and users.

It offers an important technical reference to the manufacturers for maintaining or improving the product quality and performance.

Sample installation

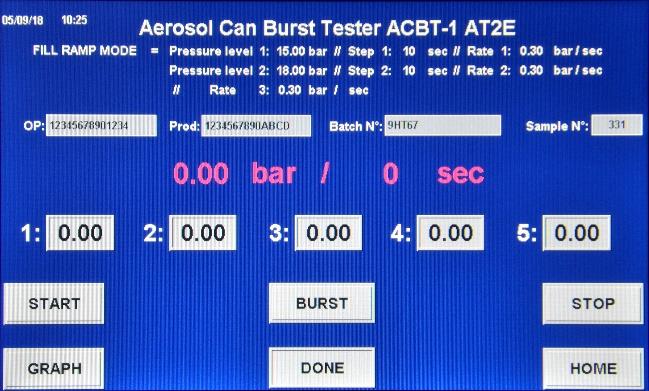

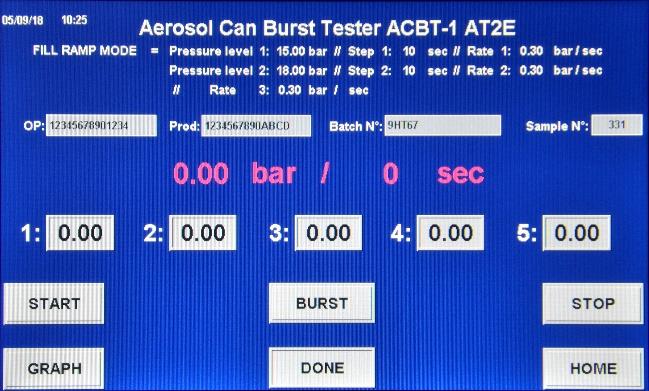

Testing screen

Test process

- Install the can sample under the affusion head and seal the sample

- Close the safety door

- Press the start button to start the test

- The affusion head will fill the sample automatically and start to pressurize when the bottle is full filled

- Pressurize the sample till the cone deforms

- Keep pressuring till the dome deforms

- Keep pressurizing till the can bursts

- The deform and burst value will be recorded automatically and display on the screen

- Stop pressurizing

- Open the door and take out the sample

01

Characteristics

- PLC integrated & High resolution touch screen control

- Three test cycles (Fill ramp mode, Burst mode and Custom mode) satisfies different test request

- Easy operation

- Easy sample installing with auto clamping and water filling system

- Linear pressurization

- User defines the product lot number and sequence number

- Review the real-time testing curve

- Stainless steel design ensures the durability of tester

- Advanced safe door design ensures the safety of operator during a test

- RS232 output

- Can store 10 operators and 30 products

02

Technical Specifications

- Testing range: 0-40 bar

- Resolution: 0.01 bar

- Accuracy: ±0.5% F.S.

- Unit: bar / psi

- Sample range: 25.4 (1”) aperture, standard 3-pcs and mono-block aerosol can

- Air supply: 5 – 8 bar

- Output: RS232

- Power: 115 V / 230 V, 50-60Hz

- Dimensions: 730 (L) x 500 (W) x 870 (H) mm

- Net weight: 80 kg

03

Optional Parts

- Mini printer

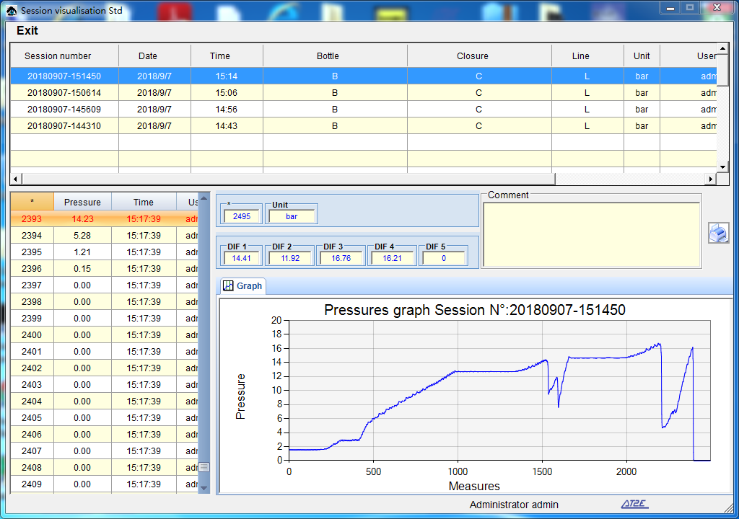

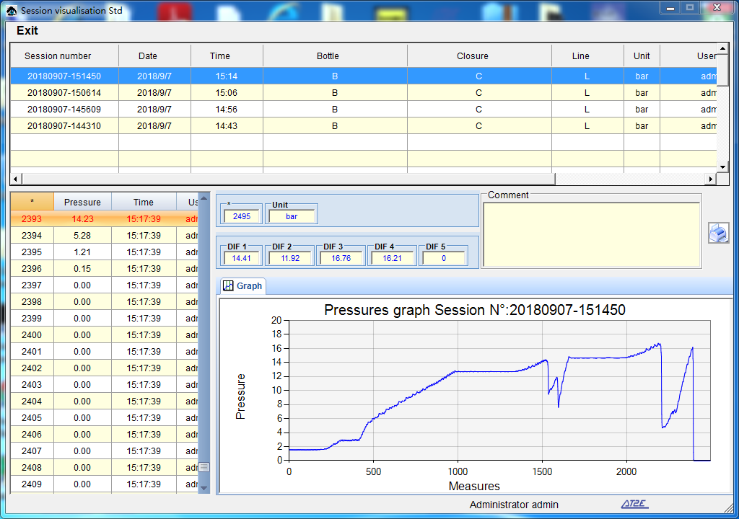

- QualiBurstPlus professional software

04

Mini printer (Optional)

“QualiBurstPlus” professional software(Optional)