Left side view

Right side view

Description

AT2E SSA-D secure seal analyzer is for testing the secure seal performance of products.

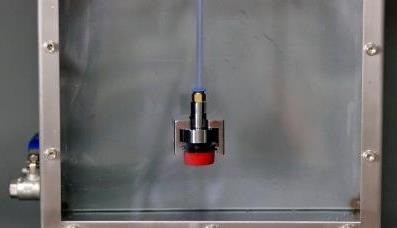

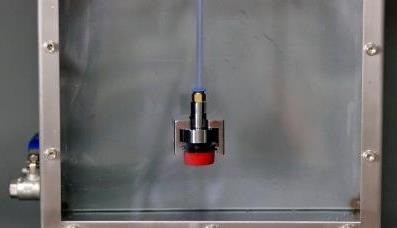

With AT2E patent needle, itmakes the installation and piercing very quick and easy in any medium. By vacuum technology and special design, the needle uses a function of self-holding on the tested products.

However, the SSA-D can be compatible with usingthe needle of the classic Secure Seal Tester (typical screwed needle). It’s stainless steel design makes it resistant of any explosion during the test and ensures the safety of the operator.

SSA-D is equipped with a touching screen. It’s visual and easy to operate. Adjustable pressure and holding time stage setting meets different test requests of various products.

Test interface

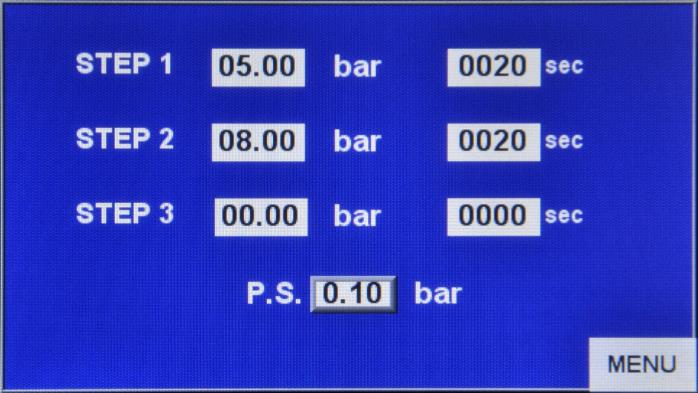

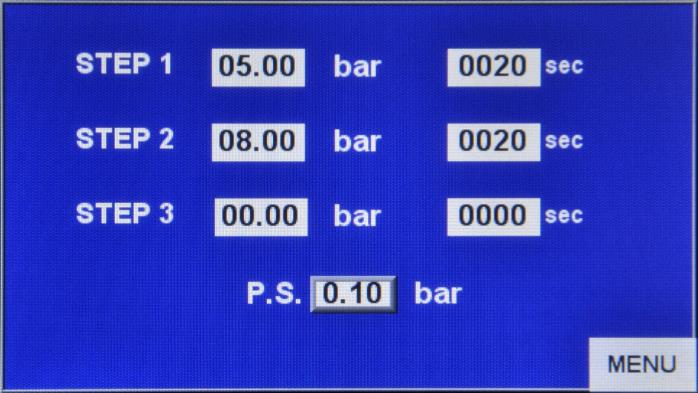

Pressure and holding time setting interface

Optional 3 position model: SSA-D-3

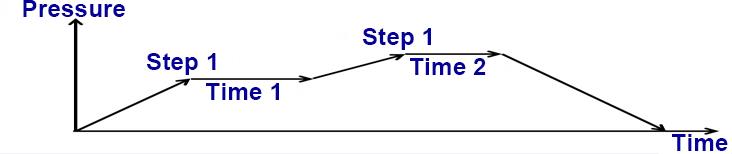

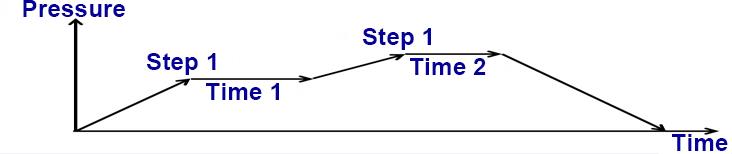

Testing curve

Technical specifications

- Measuring range: 0 to 16.00 bar

- Resolution: 0.01 bar

- Tests on bottles, cans and preforms

- AT2E patent special needle

- Touching screen display

- Units: bar / Psi

- Stainless steel secured device

- Stages pressurizing rate adjustable (regulator)

- 2 stages of pressure and holding time setting

- Net weight: 30 kg

- Resistant to explosions

- Setting maximum pressure: 16 bar

- Compatible with typical screwed needles

- 5-8 bar pressure source for vacuum function

- 0-16 bar pressure source for testing

- Power supply: AC 110 - 240 V 50/60 Hz

- Overall size: 400 (L) x 550 (W) x 750 (H) mm

01

Optional parts

- 3 stages of pressure and holding time setting

- Cutting tool for cap test

- Cap holder

- Bottle can needle

- Anti-burst frame

- Typical screwed needle

- Optional model SSA-D-3

02

Anti-burst frame

Cutting tool

Cap holder

Typical screwed needle

Bottle Can Needle

Quick cutting tool

Cap test