Description

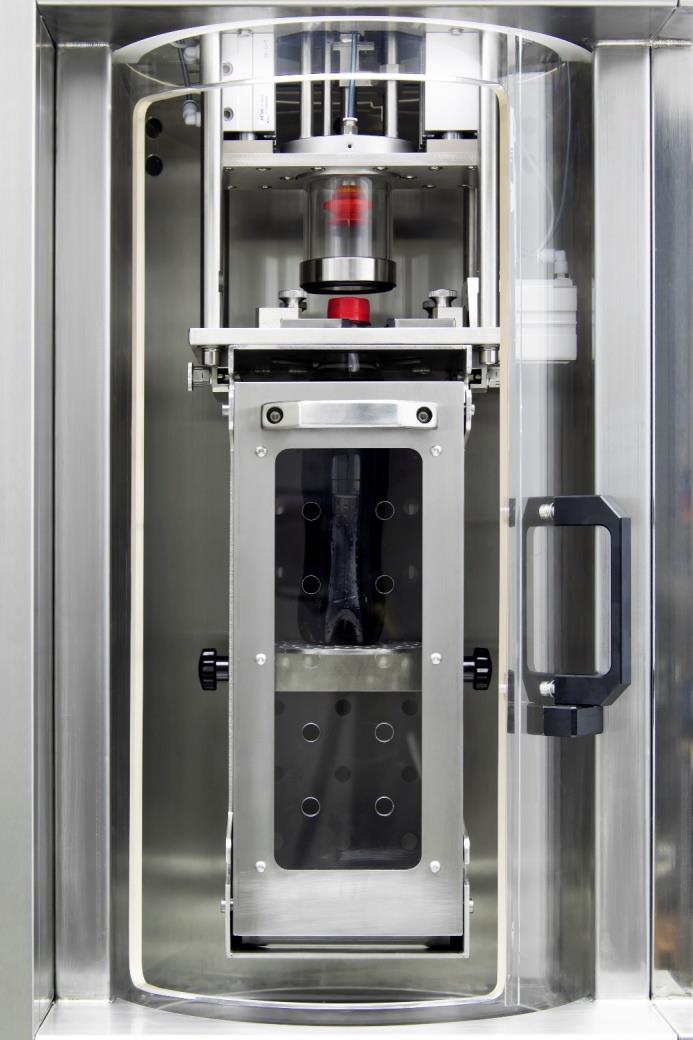

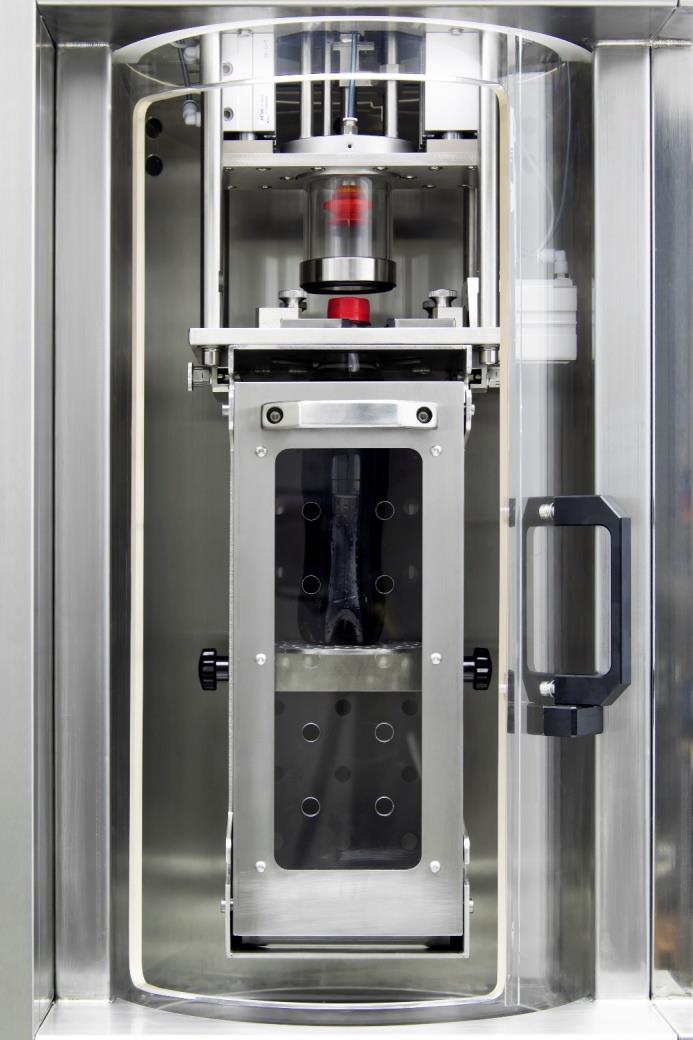

AT2E SSA-AUTO-F Secure Seal Analyzer is for testing the secure seal performance on products. It's a full-automaticinstrument with automated piercing, pressurizing and leak detecting process.

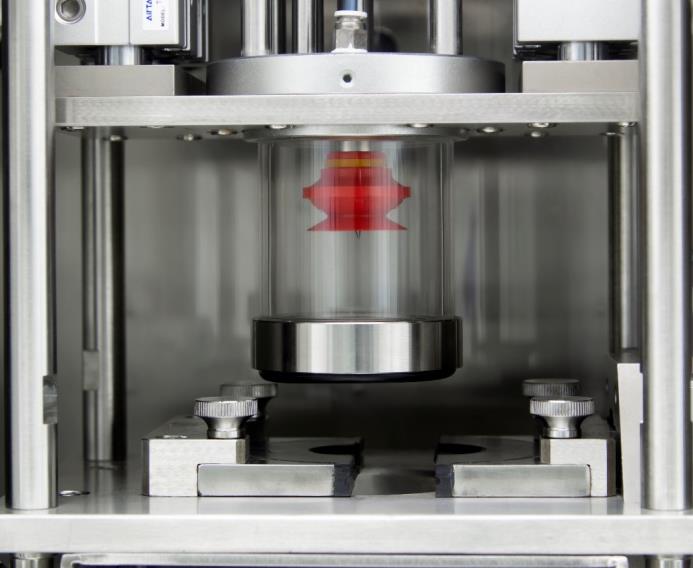

Integrated with AT2E patented piercing unit, it allows automated installation. By vacuum technology and special design, the needle uses a function of self-holding on the product being tested.

During the test process, system automatically detects whether there is leakage occurred in the sample. When leakage is detected, the test will be stopped and the maximum pressure value at which the leakage occurred will be recorded automatically.

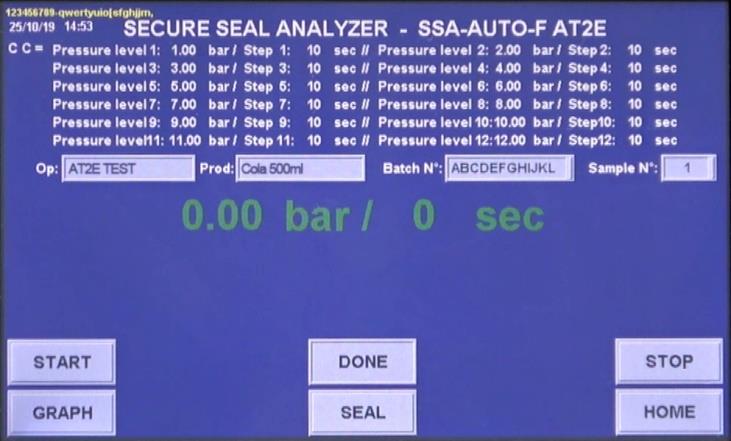

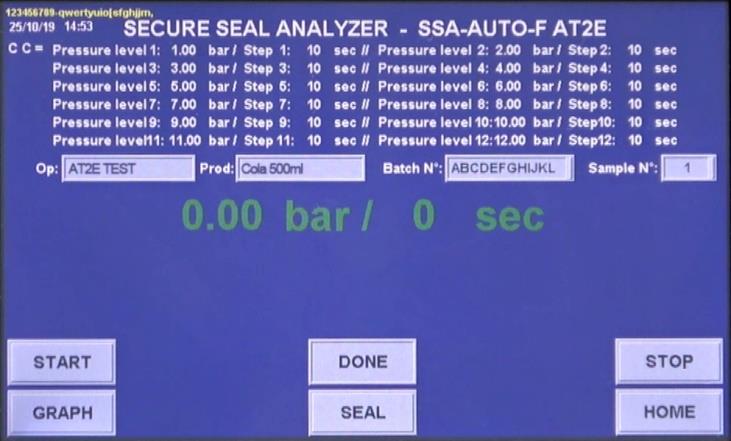

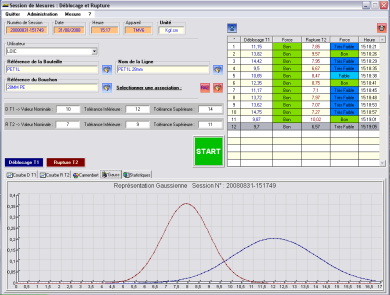

Test interface

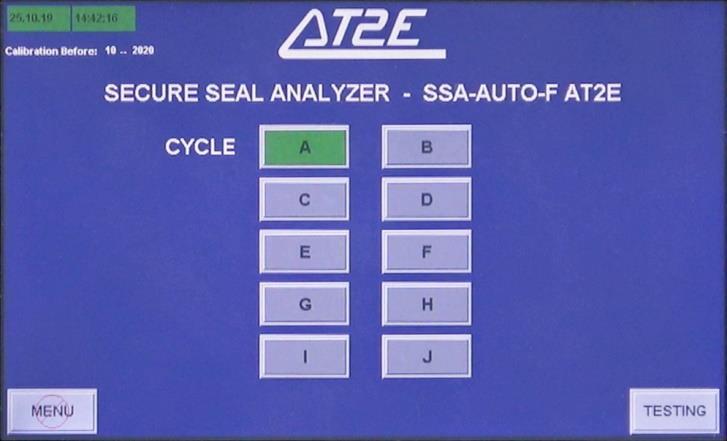

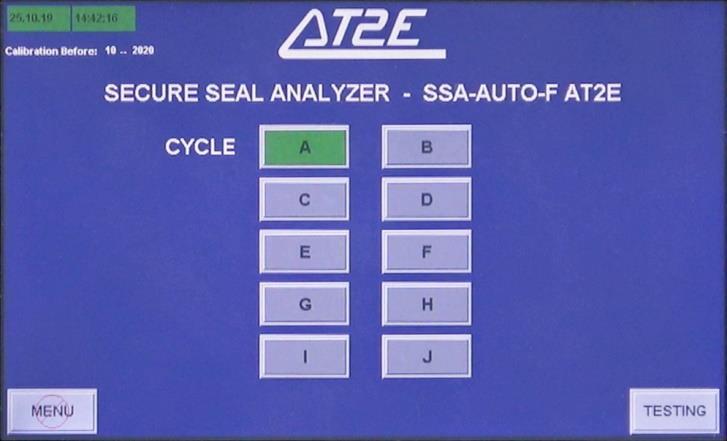

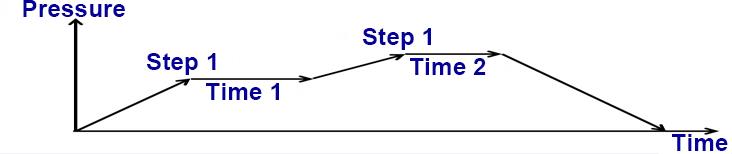

Test cycle selecting screen

The SSA-AUTO-F offers the following advantages over traditional

water bath leak testers :

- Full-automatic testing, operator just need to install the sample, select the pre-defined mode and press start button to start the test. Then the instrument will complete the whole process and record the result, which realized a true automatic testing process.

- Equipped with the high-precision sensing system, it is able to detect the leakage automatically and accurately, which makes the test results more reliable.

- Innovative water-free design, environmental friendly and more compatible and adaptable to different working environment, more convenient to use and maintain.

With inner pressure measuring

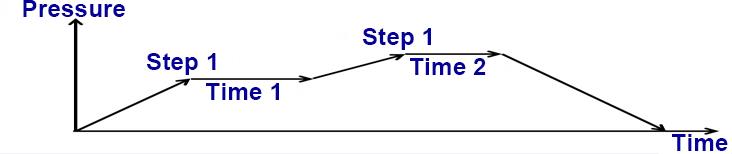

Testing curve

Technical specifications

- Measuring range: 0 to 16.00 bar

- Inner pressure measuring range: 0 to 8.00 bar (optional)

- Units: bar & psi

- Resolution: 0.01 bar

- Tests on bottles, cans and preforms

- Equipped with the touching screen, visual and easy to operate.

- Sample range: 350 mm in height & 120 mm in diameter

- AT2E patented piercing unit

- Touching screen display

- Stainless steel secured device: Resistant to explosions

- Up to 12 stages of pressure, pressurizing rate andholding time setting

- Testing curve review

- 30 products memorization

- 10 operators memorization

- Configuration by administration passwords

- Dynamic display: Real-time pressure / Vacuum levelPressure holding time / hour / date

- Display: product name / operator / batch N° / sample N°

- Maximum pressure overload protection setting

- 0-16 bar pressure source for testing

- RS232 output (used to connect to software)

- Overall size: 860 (L) x 580 (W) x 1060 (H) mm

- Net weight: 100 kg

01

Optional parts

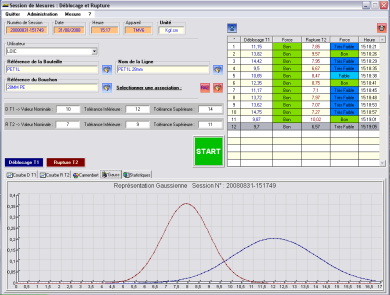

- “QUALIPRESS” software

- Custom-made clamp

- Inner pressure measuring integrated model

- Multi-positions model

- External booster

Automated piercing and testing with AT2E patent needle

02

"Qualipress" software (Optional)

SSA-AUTO Multipositions