Description

The SSA-PLC-12 Secure Seal Analyzer (12 Positions) is a special instrument developed by AT2E for control of the secure seal performance of caps on preforms.

Technical specifications

- Measure range: 00.00 – 16.00 bar

- Accuracy: ± 0.5 % F.S.

- Display resolution: 0.01 Bar

- Units: Bar, psi

- Dimensions: 750 (L) x 900 (W) x 550 (H) mm

- 7” LCD touch screen

- Up to 4 pressurization steps (4 target pressure)

- Max. testing pressure: 16 Bar

- Air supply: 0-16 Bar (Air supply ≥Max. testing pressure)

01

Attributes

- Muilt-position design, more convenient and efficient.

- PLC control ensures the high accuracy and reliability.

- Stainless steel frame, more safe and duable.

- Flexible position selection, each position can be controlled separately by system, users can choose to enable the positions (from 1 to 12) according to their needs.

- Linear pressurizing, able to set up to 4 pressurization steps, and hold the pressure according to the predefined period.

- Auto pressure compensation during test process

- Special designed clamping device, enhanced the sealing performance of test.

- Anti-explosion and clear observation window, safe and easy to observe the sample status during tests.

02

Testing procedure

Install the preform with cap

Test the preform in the water bath

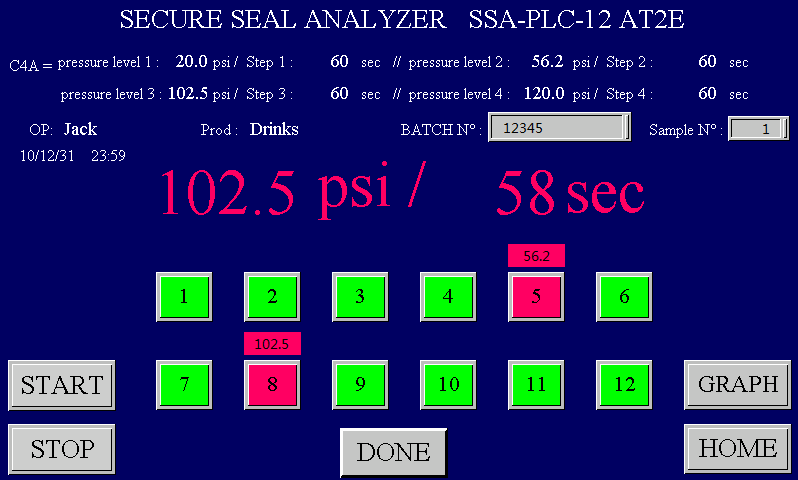

Testing screen

Test example

As per the above screen shot, during the test, the sample in #5 and #8 positions leak, press the #5 and #8 button, the button on screen will become red and system will stop pressurizing, and display the leak pressure value above the button. System will generate a data table for each test to record the test pressure of every position.

In the table, the red button position will be display as “NG”, and with the leakage pressure value, green button (normal) position will be display as “OK”, and with the target testing pressure. The data table can also be printed out through the micro printer.