Description

The AT2E ADATMV5-S On line Automated Torque Tester is a quality control system which has been designed for connecting to the production lines to carry out the automatic torque control and provide measure data for instant inspection. The system was developed base on our torque control experience over 25 years, with the aim to CANCEL operators’ influence factors so as to provide the optimal torque control with more accurate and reliable results and better reproducibility.

Besides the regular torque inspection, the ADATMV5-S is able to perform the non-destructive inspection which is not possible to achieve by manual inspection. With non-destructive inspection, the seal integrity of the product is still intact and no microbial contamination risk.

The system can also be installed in the laboratory as a semi-automatic torque control system with manual sample installation.

Customize screen display and cycles are available, flexibly for different control requirements.

Opening - Closing head with optional module automatic

Opening - Closing head with optional module automatic

Technical specifications

- Free operator torque controller (on-line)

- Legal weighing control suitable in option

- Secure seal test suitable (automatic bubble point control)

- Using by touch screen

- Measures in opening and closing directions

- Measuring range: 00.00 to 99.00 Kgf.cm

- 6 measuring cycles:

Torque closing / Reach position / Release + break / Release + break + over screw / Non-destructive test /– (MORE ON REQUEST)

- Units: Kgf.cm / Inch.lbs / N.cm / N.m

- Rotating angle & speed adjustable under certain cycle

- Accuracy: +/- 0.5 % of full scale

- 30 products memory

- 30 thresholds (limits) option

- 10 operators memory

- Special multi format system for both bottle and preform

- Dynamometric system

- Configuration by protected password (administrator)

- Memorization up to 100 measures

- Dynamic display: statistics, hour, date

- Display: product name, operator, batch N°, line N°

- 1 RS232 output and 1 printer output (software & printer)

- Language: English / French / Chinese

- Delivered with calibration certificate accord with ASTM/ NIST/COFRAC/ DKD ENAC / UKAS

- Easy-fast selector for cycles

- Customized cycles

- Easy-fast selector for cycles

- Special pneumatic chuck available

- Auto-mode (Automatic start-stop detection system need to be equipped)

- Special auto mode with head number – filler storage

- Easy-fast selector for cycles

- AC 220V (AC 110V optional)

01

Automated part

- Safety door

- Automatic zero before restarting cycle

- Settable height of column for all samples

Mechanical specifications

- Stainless steel Frame

- Choice of measuring chucks: Beverage / Cosmetic / Pharmacy

- Dimensions:

- 1075 (L) x 590 (W) x 1390 (H) mm

- Weight: 120 kg

Optional parts

- Mini printer

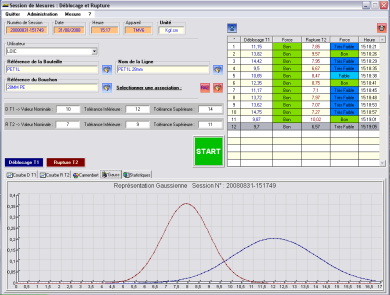

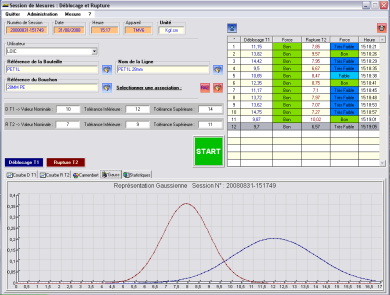

- QUALITORQ Software

- Customized display & cycles

- Calibration pack

- Dynamometric system

- Automatic start-stop detection system

QUALITORQ software (Optional)

QUALITORQ software (Optional)

02

Calibration pack (Optional)

Dynamometric system (Optional)

Automatic squeezing clamping system for PET packaging (Optional)