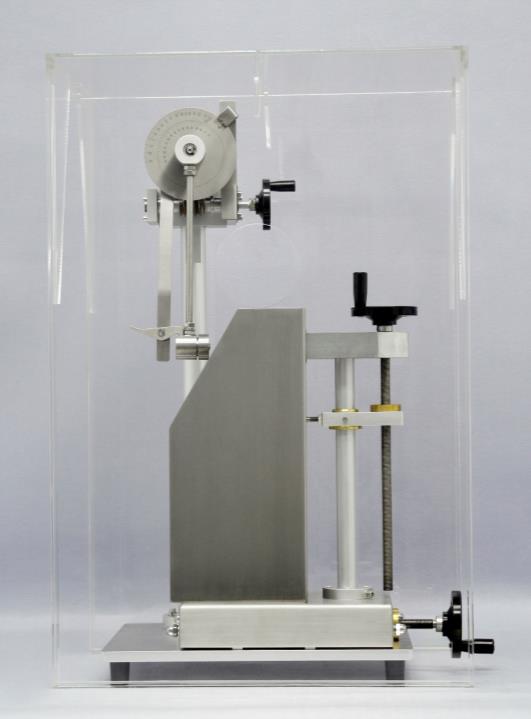

Standard GBIT

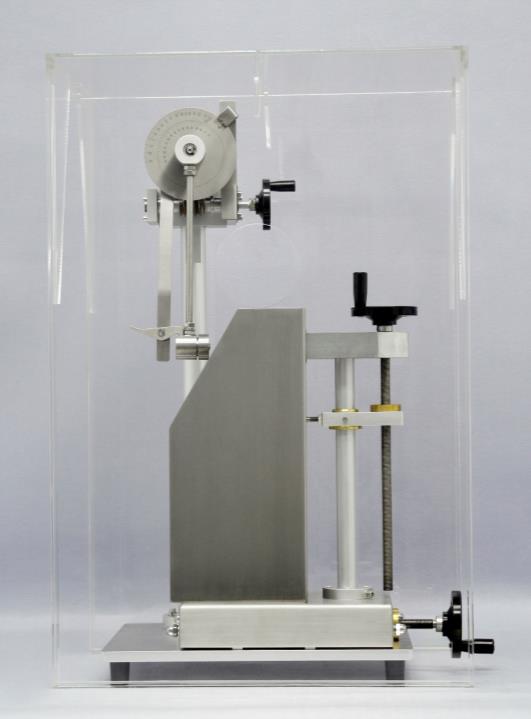

GBIT with Safety frame (Optional)

Special instrument for testing the impact resistance ability of various glass bottles and jars.

Attribute

- The sample clamp is able to move flexibly on vertical or horizontal direction, convenient for adjusting the sample position

- Instrument design accord with the law of the conservation of energy, ensured the testing accuracy and test reliability

- Stable and accurate pendulum able to rotate and release freely

- With stainless steel safety shield

- User-friendly design, easier for operation

01

Principle

Base on the law of conservation of energy conversion, the energy that pendulum impact on the bottle is determined by its potential energy where it was hung. When the pendulum was hung on a certain angle, its potential energy is corresponding to a certain value, and the impact energy on the bottle is also corresponding to a set value. According to the conversion relationship of pendulum hanging angle and its impact energy, to pre-define a certain energy value of the pendulum by defining the hanging value, then release it to impact on the bottle, and observe whether the bottle was damaged or not, so that to judge the impact resistance of the bottle

02

Specification

- Sample diameter range: Ф30 -130 mm (clamps for other range available)

- Impact height: 5 - 305 mm (other range by order)

- Max. impact energy: 3.2 J

- Resolution:

0.1J for each lattice (when impact energy larger than 0.6J) 0.05J for each lattice (when impact energy less than 0.6J)

- Energy loss: ≤1.5% F.S.

- Dimensions: 580 mm *350 mm *850 mm

03