The BTLT-2 is an instrument for testing the resistance to Top load effort on glass containers. It has been widely used by the glass container manufacturers and users. As a standard testing instrument for the glass container industry, it offers an important technical reference to the manufacturers for maintaining or improving the product quality and performance.

Designed for easy operation and maintenance, comply with the testing standard of ISO 8113:2004.

The top load test of containers is made up to a predefined pressure point (trial test) or until destruction.

Characteristic

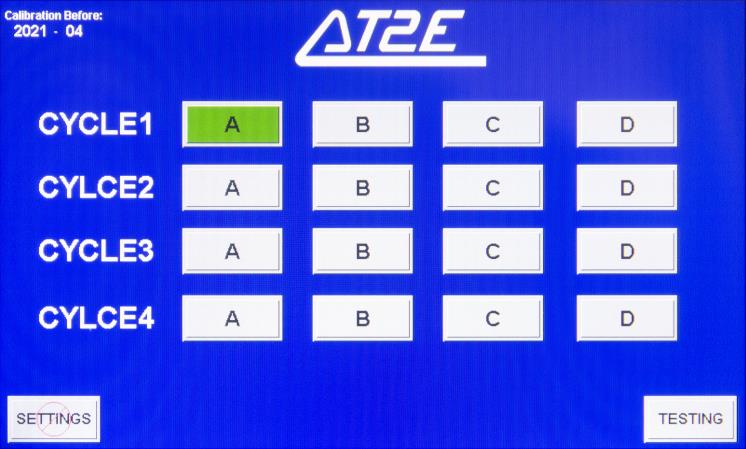

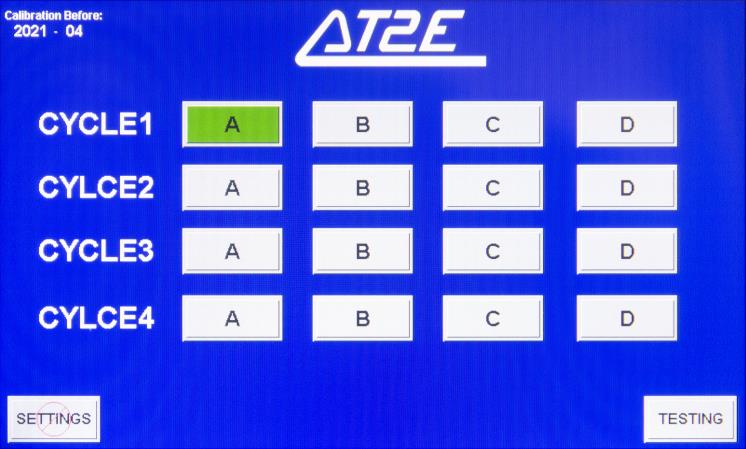

- User defined test cycle (up to 4 steps of pressure and holding time) satisfies different test request

- PLC integrated & Touch screen control

- Easy operation

- Can store 10 operators and 30 products

- Available for both compression (top load) test the traction (pull) test

- User define the product lot number and sequence number

- Overload protection

- Advanced safe door design ensures the safety of operator during a test

- RS232 output interface, can be connected to printer or data acquisition software

- Reviews the real-time testing curve

- Custom-made inserts for different types of samples, easier sample installation and more accurate on pressure point

- Huge sample capacity, up to 600 mm in bottle height (custom-made model)

- Testing speed adjustable

- AT2E Patented trash bin design, more safety for operating and easier for scrap cleaning

- Maximum top load force up to 2000 Kgf / 20000 N

- Stainless steel frame and aluminum parts, more sturdy and durable

Testing chamber and operating screen

01

Technical specifications

- Measure range: 0 – 20 KN (Others by order)

- Sample height: 125-400 mm (standard model, other range by order)

- Sample diameter: 160 mm max. (standard model, other range by order)

- Units: KN (Or Kgf, please specify when order)

- Resolution: 0.01 KN

- Power supply: AC 220V (AC 110V optional)

- Dimensions: 744 (L) x 493 (W) x 1160 (H) mm

- Weight: 130 kg

02

Easy cycle selection screen

Optional parts

- Mini printer

- High accuracy calibration unit

- Data management software

03