Testing procedure ("PS" mode)

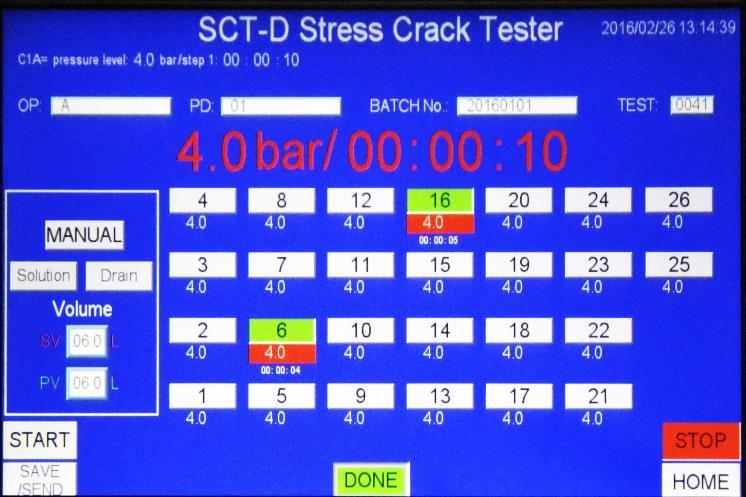

As per the above screen shot, during the test, the bottles in #6 and #16 positions leak, the lights of positions #6 and #16 will become green automatically and system will stop pressurizing the corresponding positions. Or, operator can press the position button to stop pressurizing if any tiny leakage occurs by observation.

Leak pressure value and time will be displayed below the button. System will also generate a data table for each test to record the test pressure of each position.

In the table, positionwith green light will be displayed as “NG” with the leakage pressure value. Normal position will be displayed as “OK” with the predefined pressure value. The data table can also be printed out through the mini printer.